Our technical department is at your disposal to satisfy every specific need.

DESIGN OF MOULDS

ALUMINIUM DIE-CASTING

SANDBLASTING

MECHANICAL FINISHING

FROM THE MOULD TO THE FINISHED PRODUCT

Serfinmec has thirty years of experience in the field of castings and finishes of aluminium and zamak products that led it to reach a high quality standard, always demonstrating a strong vision towards innovation.

Highly qualified and experienced personnel in the field of die-casting aluminum, allows us to offer customers assistance in design and engineering.

Our production philosophy accompanies the customer from the idea of a product, to the realization of the same, following with care all the steps from the design, to the production and the working until the final assembly.

Leader: interview with Sergio vezzoli

YOU HAVE THE IDEA. WE HAVE THE SOLUTIONS.

The deep knowledge of the aluminium and zamak sector has led Serfinmec to offer a complete service that includes the design and construction of die casting moulds.

For the realization of the die-casting we collaborate with numerous foundries where there are all types of presses to meet every request: from the smallest of 200 tons to the largest of 1200 tons.

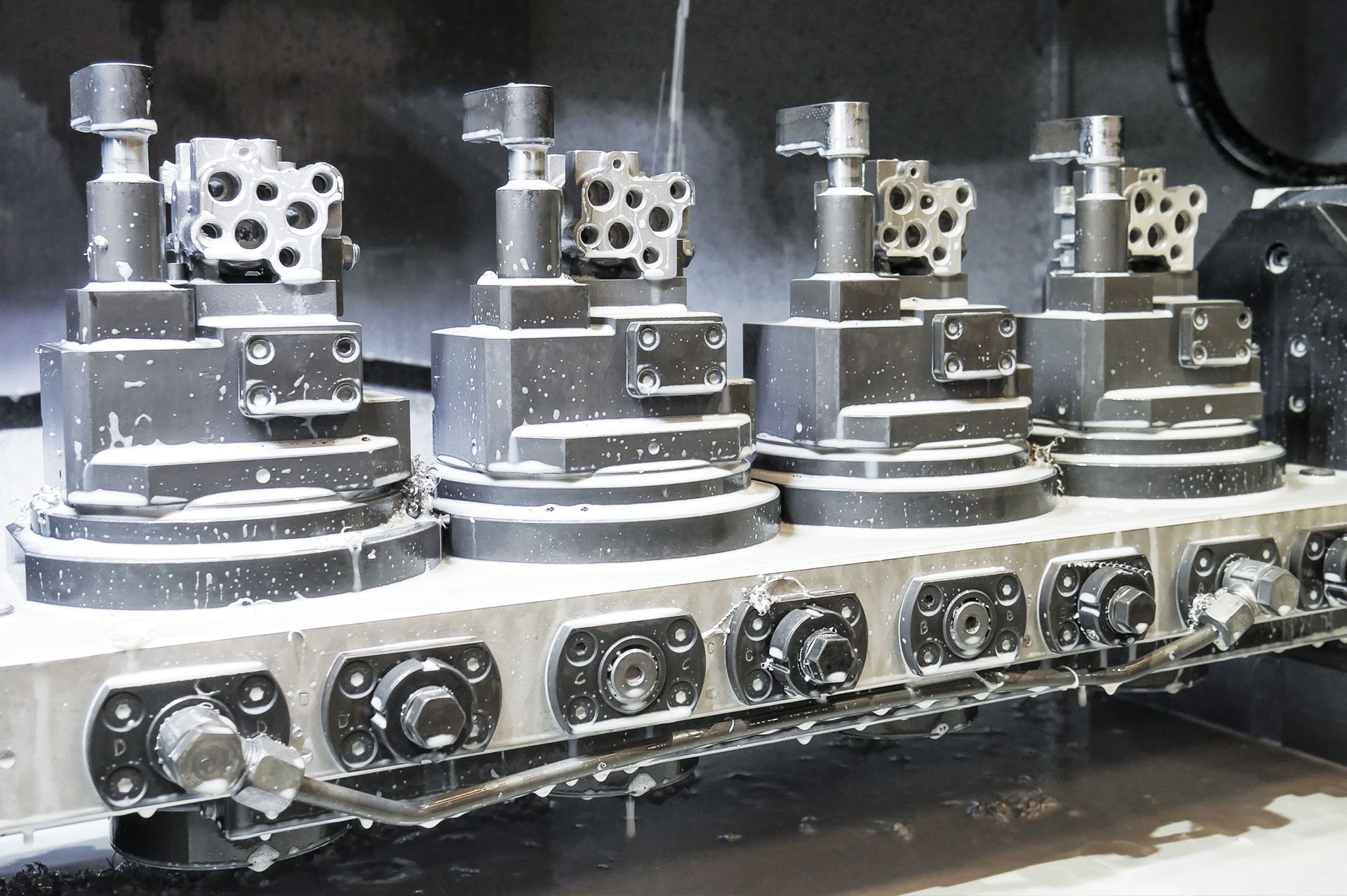

We have fully automatic machining centers (CNC), tunnel through sandblasting machines and ramping belt shotblasting machines. Qualified staff takes care of the finishing and surface cleaning of the die cast parts thanks to the use of manual and robotic grinding equipment. Serfinmec also specializes in the assembly of mechanisms on processed products. The material used for assembly is subjected to special quality controls to always ensure the higher standard.